Best Epoxy For Concrete Floors (2024 Update)

When it comes to choosing the best epoxy for concrete floors, there are several important factors to consider before making a purchase. The right epoxy coating can transform dull, porous concrete into an attractive, durable and easy-to-clean surface. However, not all epoxy products are created equal when used on concrete floors. Homeowners need to evaluate the type of concrete, surface preparation needs, desired finish and appearance, application method, and product durability.

What type of look are you trying to achieve? Do you want a basic, single-coat epoxy, a clear top-coat, or colored flakes for decorative pizzazz? Determining the aesthetic you prefer helps narrow suitable epoxy options. You’ll also need to examine the concrete’s condition. Is it new or existing, smooth or porous, painted or uncoated? This determines what type of prep work is required before applying epoxy. Mixing the proper prep with the right product creates the strongest bond.

When researching and comparing epoxy kits, key considerations are coverage area, thickness, dry and cure times, application method, number of coats needed, and longevity. Are you able to apply the epoxy yourself or will you need to hire a professional? Does the product resist chemicals, scratches, cracks, and peeling long-term? Reading product details and reviews prevents choosing the wrong epoxy and saves time and money down the road.

With the variety of epoxy products available, it can get overwhelming deciding what will work best to transform your concrete floors. Doing your homework on needed prep, choosing quality epoxy suited for concrete, and properly applying the coating results in durable, versatile and beautiful floors. Taking your time upfront makes for a smooth epoxy application and years of enjoyment.

10 Best Epoxy For Concrete Floors

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

Ideal for producing crystal clear epoxy casts, coatings, and woodwork projects such as river tables, bartops, and countertops.

|

|

||

|

2

|

It is ideal for coating concrete surfaces such as garage floors, basements, porches, patios, and more with vibrant colors.

|

|

||

|

3

|

The product is ideal for commercial and industrial flooring, providing a durable epoxy coating.

|

|

||

|

4

|

Ideal for coating garage floors up to 250 sq.ft. with a gray base and durable clear top coat for added protection.

|

|

||

|

5

|

Ideal for fixing and repairing cracks and holes in concrete surfaces such as driveways, sidewalks, and patios.

|

|

||

|

6

|

It is ideal for garage floors up to 500 sq.ft. providing a durable, glossy, and easy-to-clean surface with impressive protection.

|

|

||

|

7

|

This product is ideal for coating garage floors, basements, and concrete or plywood surfaces with a light gray epoxy resin.

|

|

||

|

8

|

The product is ideal for filling and repairing cracks, holes, pits, and spalling in concrete floors.

|

|

||

|

9

|

It is ideal for creating a clear and glossy coating on table tops with minimal bubbles that is UV resistant.

|

|

||

|

10

|

The product is ideal for coating garage floors with a durable and long-lasting finish.

|

|

1. Crystal Clear Epoxy Kit For Art & Furniture.

Introducing the perfect art resin for river tables, live edge tables, countertops, and bar tops. This specially formulated resin is designed to provide exceptional results when used with pigment powder, mica powder, alcohol ink, resin dyes, and resin tints.

Experience the self-leveling properties of this high-gloss resin that delivers a clear, scratch-resistant, and water-resistant finish. The highest UV resistance ensures that your artwork remains vibrant and vivid for years to come.

This DIY epoxy kit mixer comes with clear epoxy resin and hardener, providing you with everything you need to create stunning pieces of art. The original manufacturer has been in this business for over 60 years, and this product is proudly made in the USA.

Get ready to explore your creativity and produce high-quality artwork with this exceptional product. Whether you're a professional artist or a DIY enthusiast, this art resin is perfect for a wide range of applications.

Order now and experience the highest quality art resin available on the market.

2. Duragrade Concrete Coating: High-Performance & Vibrant!

The Premier Garage Floor Paint and Concrete Paint is a high-quality product that guarantees excellent results. This top-quality paint is perfect for use on both indoor and outdoor surfaces, making it versatile and convenient. It is made in the USA at a US-based company, ensuring that it is of the highest quality.

This paint is incredibly easy to use, as it can be applied directly to concrete without requiring any acid etching. It also does not need a primer, basecoat, or topcoat, making the process even more straightforward. Its ease of use makes it ideal for DIY enthusiasts who want to transform their garage floors or concrete surfaces without the hassle of complicated procedures.

The Premier Garage Floor Paint and Concrete Paint is also incredibly durable. It is scratch, chip, chemical, and UV-resistant, ensuring that it can withstand even the toughest conditions. This means that it will maintain its appearance for a long time, even with regular use.

When it comes to versatility, this paint is a top contender. It can be used on a variety of surfaces, including garage floors, patios, basement floors, and even industrial floors. This makes it a perfect choice for those who want to achieve a consistent look throughout their property.

3. Commercial Industrial Epoxy Flooring- 30 Gallon"good" Kit (Gray Base)

This high-performance coating kit is designed to cover up to 5,000 square feet at 9.7 mils. It comes with everything that you need to complete your project, making it a convenient option for those who want to get started right away. Made in the USA, this product comes with a lifetime guarantee and is 10 times more durable than big box store brands and water-based epoxies.

One of the great things about this coating is that it has no odor, making it a great option for indoor use. Additionally, it is slip-resistant, ensuring that you can use it safely in a variety of conditions. The easy application process makes it a great choice for those who are new to this type of project.

This coating is 100% solids, which means that it is resistant to chemicals, salt, oil, and hot tires. This makes it a great option for garages, workshops, and other high-traffic areas. With its impressive resistance to wear and tear, you can be confident that this coating will stand up to the demands of your space.

4. Garage Upgrade: Epoxy-Coat Kit With Gray Flakes

The Gray Base Coat with Gray Blend Flakes is an ideal solution for home and commercial flooring projects. With a coverage of 250 square feet and a thickness of 19.4 mils, it is suitable for various surfaces such as garage floors, basement floors, concrete floors, wood floors, and more.

The kit comes with everything that is required for the project, including 2-part 100% solids epoxy, clear top coat epoxy, decorative flakes, and application tools. This ensures that you have all the necessary components to achieve a professional-looking finish.

The product boasts a lifetime guarantee and is made in the USA. It is 10 times more durable than big box store brands and water-based epoxies. This high-performance coating is designed to withstand harsh conditions and offer long-lasting protection.

One of the most significant advantages of this product is that it is odorless, making it easy and safe to use. Additionally, it is slip-resistant, ensuring the safety of the users. The application process is straightforward, and the product offers a high gloss finish that is resistant to chemicals, salt, oil, and hot tires.

5. Rust-Oleum 301012 Concrete Patch & Repair, 24 Oz, Gray

Looking for a reliable solution to fix concrete cracks and holes? Look no further than this two-part industrial-strength epoxy, ideal for both indoor and outdoor use.

This fast-curing product is designed to permanently bond concrete without shrinking or cracking, creating an extremely hard surface that is even stronger than concrete itself. And, unlike other concrete repair products, this epoxy contains no unpleasant odors, making it a great choice for use in enclosed spaces.

In just eight hours, this epoxy allows for concrete to be painted or coated, making it a versatile option for a variety of projects. Plus, it's a universal product that works with any concrete coating, so you can be confident that it will work for your specific needs.

Whether you're repairing cracks and holes in your driveway, patio, or other concrete surfaces, this industrial-strength epoxy is a reliable and effective solution that will help you achieve professional-looking results that last. So why wait? Try it out today and see the difference for yourself!

6. Garage Ultimate Epoxy Kit – Black & Gray

The Black with Gray Blend Flakes Kit is the perfect solution for anyone looking to revamp their floors. This kit includes everything needed for a successful project, including 2 Part 100% Solids Epoxy, Clear Top Coat Epoxy, Decorative Flakes, and Application Tools. With a coverage of 500 Sq Ft at 19.4 mils, this kit is ideal for garage floors, basement floors, concrete floors, wood floors, and more.

The Black with Gray Blend Flakes Kit is proudly made in the USA and comes with a lifetime guarantee, ensuring its quality and durability. This kit is 10 times more durable than water-based epoxy and big box store brands, making it a reliable choice for any flooring project.

One of the best features of this kit is that it has no odor, making it easy to work with and perfect for indoor use. Additionally, the Black with Gray Blend Flakes Kit is slip-resistant, ensuring safety in high traffic areas. The kit is also self-leveling, making application easy and hassle-free.

The Black with Gray Blend Flakes Kit offers a high gloss finish, giving any floor a sleek and polished look. Its decorative flakes add a touch of personality and style to any space. This kit is also incredibly easy to apply, making it a great option for both professionals and DIYers.

7. Vibrant Gray Garage And Basement Epoxy Kit

Introducing a highly versatile and durable solution for surface coating needs – a 100% solids, odorless, non-water based professional grade epoxy that offers a range of benefits. With a coverage of 125 sq. ft to 170 sq. ft per gallon, this product is perfect for a variety of surfaces including plywood, concrete, and bar tops.

One of the most notable features of this epoxy is its impact resistance, which offers a super high gloss, durable finish that is ultra-premium, non-cracking, and non-chipping. It is designed to withstand the test of time and can handle heavy traffic without showing any signs of wear and tear.

In addition, this epoxy is zero VOC and Vohap-free, making it a safe and environmentally friendly product to use. It is also UV resistant, which means it won't fade or yellow over time even with constant exposure to sunlight.

Each kit comes with application instructions that are easy to follow, ensuring that even those without prior experience can achieve professional-looking results. So, whether you're a DIY enthusiast or a professional contractor, this product is a reliable and effective solution that you can count on.

8. Epoxy Resurfacer: Repair Concrete Cracks In Seconds!

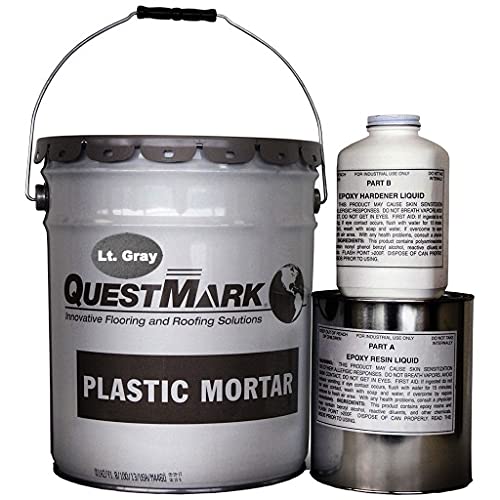

The epoxy mortar being reviewed is a top-performing solution for patching or resurfacing concrete floors. With impressive flexural, tensile, and compressive strength, it is ideal for floors that require patching or resurfacing without a lot of chemical and impact resistance. The product's specification sheet provides detailed information.

When applied at 70 degrees F, the pot life of this epoxy mortar is 20-30 minutes. It can be recoated in 6-7 hours, and light foot traffic is possible in just 12-14 hours. For full cure (heavy traffic), it typically takes 2-7 days.

To ensure optimal results, it's recommended that the epoxy mortar is applied to a thickness of 1/8" to 1/4". With a 5-gallon unit, coverage for this thickness is approximately 19.15 sq ft.

The system for this product consists of resin, hardener, and aggregate components. It's important to note that the epoxy mortar is proudly manufactured in the USA.

9. Clear High Gloss Epoxy Kit – Diy Perfection

Promise Epoxy is the new superpower in the home decor and art industries, created by the merger of two of the most popular epoxy brands in the U.S., ProMarine Supplies and Incredible Solutions. Their premium crystal clear epoxy is designed for a variety of applications, including table tops, bars, wood finishes, see-through encapsulations, art work, and more. The custom epoxy formulation allows for minimal bubbles, goes on smooth, and helps eliminate fish eyes, craters, and various other imperfections.

One of the best things about Promise Epoxy is that it is manufactured in the USA, so you can rest assured that you are getting the very best product produced. The epoxy is safe once fully and properly cured, and has a low odor.

Using Promise Epoxy is easy thanks to its 1:1 mixture ratio. No need to worry about spending hours gathering materials and wasting your money, only to have the epoxy resin not level, be full of bubbles, or start turning yellow. Promise Epoxy is high gloss, UV resistant, and self-leveling, making it easy to create beautiful, professional-looking projects.

Promise Epoxy also offers rock-hard versatility. They only produce a tough, high gloss, and water-resistant coating, ensuring that their product will last through the test of time.

If you're unsure about how to use Promise Epoxy, their knowledgeable customer support staff is available to help coach you along. Whether you're a first-time user or a pro, they can help with bar tops, tabletops, river tables, jewelry, coffee tables, countertops, serving trays, and more. Promise Epoxy has pretty much seen it all.

10. Rust-Oleum 317286 Rocksolid Polycuramine Garage Floor Coating, 1 Car Kit, Dark Gray

This polycuramine concrete coating is the perfect choice for anyone looking to enhance the durability of their interior concrete surfaces. The coating is specially designed to withstand heavy usage in areas such as garages, workshops, basements, and family rooms.

Unlike traditional epoxy coatings, this self-leveling, buildable formula is 20 times stronger and comes in a low odor and low VOC two-part, patented burst pouch. This innovative design ensures that the coating is easy to apply and will quickly set, providing a high-gloss finish that resists cracking, peeling, and chemical spills.

The coating is walk-on ready in just 8 to 10 hours, and vehicles can be parked on it within 24 hours. With each kit covering up to 250 sq. ft. depending on surface porosity, this product is both practical and cost-effective. Plus, there's no need to worry about hot tire pickup, as this coating is designed to resist it.

This coating provides a terrazzo flooring look that is sure to impress in any space. The high-gloss finish creates a showroom quality floor in just one coat that is sure to last for years to come. Don't settle for a subpar coating when you can have the best with this durable, polycuramine concrete coating.

Best Epoxy For Concrete Floors FAQs

Can epoxy be applied to damp concrete floors?

No, epoxy should not be applied to damp concrete floors. The moisture in the concrete can interfere with the adhesion of the epoxy and cause it to peel or bubble. Before applying epoxy, it is important to ensure that the concrete surface is completely dry and free of any moisture. This can be achieved by using a moisture meter to check the moisture content of the concrete or by allowing the concrete to dry for a sufficient period of time. Additionally, it may be necessary to use a primer or moisture barrier to prevent moisture from seeping through the concrete and affecting the epoxy coating. It is important to follow the manufacturer's instructions and guidelines when applying epoxy to ensure a successful and long-lasting application.

Can epoxy be applied to stained or painted concrete floors?

Yes, epoxy can be applied to stained or painted concrete floors, but there are some important considerations to keep in mind. First, it's important to ensure that the existing stain or paint is well-adhered to the concrete and is not flaking or peeling. If there are any areas where the stain or paint is failing, those areas should be repaired before applying the epoxy.

Additionally, it's important to choose an epoxy that is specifically designed for use on concrete floors. These epoxies are typically formulated to withstand the heavy wear and tear that floors are subject to, and may also contain additives like slip-resistant materials or UV inhibitors.

Before applying the epoxy, the concrete should be thoroughly cleaned and any cracks or pits should be filled. Depending on the type of epoxy being used, it may also be necessary to apply a primer or etching solution to help the epoxy adhere to the concrete.

Overall, with proper preparation and the right materials, epoxy can provide a durable and attractive finish for stained or painted concrete floors.

Can epoxy be used on outdoor concrete floors?

Yes, epoxy can be used on outdoor concrete floors. In fact, it is a popular choice for outdoor concrete floors as it provides a durable and long-lasting surface that can withstand harsh weather conditions. Epoxy is a type of resin that is applied as a coating on concrete floors to protect them from damage, stains, and wear and tear. It creates a hard, glossy finish that is easy to clean and maintain.

However, it is important to note that not all epoxy coatings are suitable for outdoor use. It is essential to choose an epoxy coating that is specifically designed for outdoor use and can withstand UV radiation, temperature fluctuations, and moisture. Additionally, proper surface preparation and application techniques are crucial for achieving a successful and long-lasting epoxy coating on outdoor concrete floors. It is recommended to hire a professional contractor or consult with an expert to ensure that the proper epoxy coating is selected and applied correctly.

How do I properly prepare my concrete floor before applying epoxy?

Preparing your concrete floor properly before applying epoxy is crucial for a successful and long-lasting finish. Here are the steps you should follow:

1. Clean the floor: Remove any dirt, dust, oil, grease, or other debris from the surface. You can use a pressure washer, a stiff-bristle brush, and a degreaser to do this.

2. Fix any cracks: If there are any cracks or holes in the concrete, fill them with a concrete patching compound and let it dry completely.

3. Etch the surface: Etching the concrete will create a rough surface that will help the epoxy adhere better. You can use an acid etching solution or a mechanical grinder to do this.

4. Neutralize the surface: After etching, you need to neutralize the acid with a neutralizing solution and rinse the surface thoroughly with water.

5. Let the floor dry: Make sure the floor is completely dry before applying the epoxy. This may take several hours or even a day or two, depending on the humidity and temperature.

By following these steps, you can ensure that your concrete floor is properly prepared for the epoxy application, which will result in a durable and attractive finish.

How long does epoxy last on concrete floors?

Epoxy is an excellent coating for concrete floors, providing a durable, long-lasting finish that is resistant to moisture, chemicals, and abrasion. The lifespan of epoxy on concrete floors can vary depending on several factors, including the quality of the epoxy, the preparation of the concrete surface, and the level of traffic and wear and tear the floor experiences.

In general, high-quality epoxy coatings can last anywhere from 5 to 10 years or more on a concrete floor, with proper maintenance and care. However, the lifespan can be shorter if the concrete surface is not properly prepared before application, or if the floor is subject to heavy traffic or impact.

To ensure the maximum lifespan of epoxy on concrete floors, it is essential to follow the manufacturer's instructions for preparation and application, and to maintain the floor with regular cleaning and maintenance as needed. With proper care, an epoxy-coated concrete floor can provide a durable and long-lasting finish for many years to come.

How long does it take for epoxy to dry on concrete floors?

The drying time of epoxy on concrete floors depends on several factors such as the type of epoxy, temperature, humidity, and thickness of the coating. Typically, it takes around 24-72 hours for the epoxy to dry completely on concrete floors. However, it is always recommended to follow the manufacturer's instructions for the specific epoxy being used.

Moreover, the temperature plays a vital role in the curing process of epoxy. The ideal temperature for the epoxy to dry is between 60°F and 90°F. If the temperature is too low, it can slow down the drying process, while if it is too high, it can cause the epoxy to cure too quickly, leading to a weaker bond.

In addition to temperature, humidity also affects the drying time of epoxy. Too much humidity can cause the epoxy to take longer to dry, while low humidity can cause the epoxy to dry too quickly, leading to cracking and other issues.

Therefore, it is essential to consider all these factors while applying epoxy on concrete floors and follow the manufacturer's instructions to ensure proper drying and curing of the epoxy.

What are the benefits of using epoxy on concrete floors?

Epoxy is a durable and cost-effective material that has become a popular choice for coating concrete floors. There are several benefits to using epoxy on concrete floors.

Firstly, epoxy creates a smooth and seamless surface that is easy to clean and maintain. It is resistant to stains, chemicals, and scratches, making it ideal for high traffic areas. This makes it a popular choice for commercial and industrial floors.

Secondly, epoxy coatings can improve the appearance of concrete floors. It is available in a range of colors, patterns, and textures, and can be customized to suit any design aesthetic. This makes it a popular choice for residential properties, such as garages, basements, and even living spaces.

Thirdly, epoxy coatings can improve the safety of concrete floors. It can create a non-slip surface that reduces the risk of slips, trips, and falls. This makes it ideal for areas that are prone to moisture, such as kitchens, bathrooms, and pool decks.

Overall, using epoxy on concrete floors can provide numerous benefits, including durability, cost-effectiveness, improved appearance, and enhanced safety.

What are the best epoxy brands for concrete floors?

There are several epoxy brands that are known to be the best for concrete floors. One of the most popular brands is Rust-Oleum EpoxyShield, which is known for its durability, high-gloss finish, and resistance to chemicals and abrasions. Another top brand is Epoxy-Coat, which offers a wide range of colors and finishes, as well as a strong resistance to wear and tear.

Other top epoxy brands include ArmorPoxy, which is known for its high-gloss finish and durability, and Sherwin-Williams, which offers a range of epoxy coatings for both residential and commercial use. It's important to choose a brand that is specifically designed for concrete floors, as these coatings have unique properties that are necessary for proper adhesion and durability.

Ultimately, the best epoxy brand for your concrete floor will depend on your specific needs and preferences. Consider factors such as the level of foot traffic, type of use, and desired finish when choosing an epoxy coating for your concrete floor.

What is the difference between self-leveling and high-build epoxy for concrete floors?

Self-leveling and high-build epoxy are both commonly used for concrete floors, but they have some key differences.

Self-leveling epoxy is a thin liquid that is poured onto the floor and self-levels to create a smooth, even surface. It is typically used to level out uneven or damaged floors. Self-leveling epoxy is easy to apply and dries quickly, making it a popular choice for commercial and industrial applications.

High-build epoxy, on the other hand, is a thicker material that is applied in multiple layers to build up the coating thickness. It is typically used to create a durable, high-gloss finish that is resistant to abrasion, chemicals, and staining. High-build epoxy is ideal for areas with high traffic or heavy machinery, such as warehouses, garages, and factories.

In summary, self-leveling epoxy is used to level out floors, while high-build epoxy is used to create a durable, high-gloss finish. Both types of epoxy have their own unique benefits and applications, so it's important to choose the right one for your specific needs.

What is the recommended thickness for epoxy on concrete floors?

The recommended thickness for epoxy on concrete floors can vary depending on the specific needs of the space. In general, a minimum thickness of 2-3 millimeters is recommended for light-duty areas such as residential garages or storage rooms. For heavy-duty areas such as industrial warehouses or manufacturing facilities, a thickness of 6-8 millimeters or more may be necessary to withstand heavy traffic and equipment.

It's important to note that the thickness of the epoxy coating will also depend on the condition of the concrete surface. If the concrete is uneven or has cracks, additional preparation and a thicker coating may be necessary to ensure a smooth and durable finish. It's always best to consult with a professional epoxy flooring contractor who can assess the specific needs of your space and recommend the appropriate thickness and preparation process for your concrete surface.