Best Insulation For Mobile Home Walls (2024 Update)

Are you looking to better insulate your mobile home? Properly insulating the walls of a manufactured home is crucial for comfort and energy efficiency. There are several factors to consider when choosing insulation for mobile home walls to ensure you get the right product.

First, examine the construction of your home’s exterior walls. Mobile homes built before 1976 contain little to no factory-installed insulation. Homes built after this year have fiberglass batt insulation between wall studs. Understanding your wall’s structure will help determine if you need basic insulation between studs or a more comprehensive exterior insulation system.

Next, consider the R-value, the measurement of insulation effectiveness. A higher R-value provides better insulation. For mobile homes, an R-value between R-11 and R-22 is typically recommended for walls depending on your climate. Other factors like cost, thickness, and ease of installation should also be weighed when selecting insulation R-value.

Do you experience drafts, humidity, condensation, or mold? Does ice build up on walls in winter? Are summers uncomfortably hot? Temperature and moisture control problems can indicate insufficient wall insulation. Upgrading will improve comfort and prevent potential moisture damage.

Ready to create a warmer, more energy efficient mobile home? Determining your needs before choosing the best insulation leads to optimal comfort and cost savings. Consult a professional to evaluate your home and recommend the right wall insulation system for your manufactured housing.

10 Best Insulation For Mobile Home Walls

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

Ideal for insulating walls and ceilings with a fabric material that is 4.5 feet wide and 300 feet long.

|

|

||

|

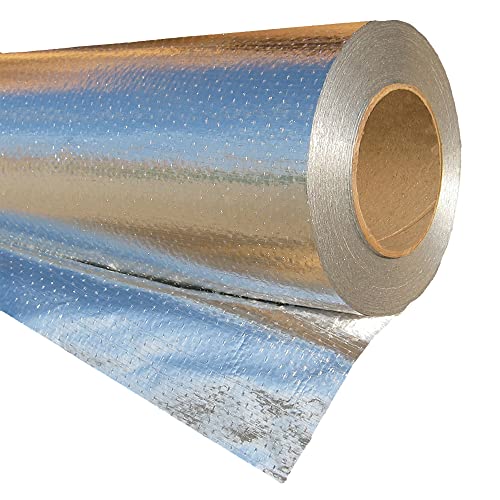

2

|

This product is ideal for insulating buildings and homes, reflecting heat and preventing cold air from entering.

|

|

||

|

3

|

Ideal for reducing heat transfer and improving energy efficiency in attics, roofs, and SCIF/RIFD structures.

|

|

||

|

4

|

Ideal for insulating homes and buildings, reducing energy consumption and creating a more comfortable indoor environment.

|

|

||

|

5

|

Ideal for insulation and reflecting heat, used in construction, HVAC, agriculture, and automotive applications.

|

|

||

|

6

|

Ideal for insulating roofs, attics, and houses to reflect radiant heat, act as a vapor barrier, and prevent tear.

|

|

||

|

7

|

Insulating pipes to save energy and prevent condensation.

|

|

||

|

8

|

It is ideal for insulating walls and attics in residential and commercial buildings.

|

|

||

|

9

|

This product is ideal for insulating attics and rooftops with a reflective barrier to improve energy efficiency and lower costs.

|

|

||

|

10

|

Insulating walls and ceilings in homes and buildings.

|

|

1. Hanes Geo Components 48311 Insuloc Wall And Ceiling Insulation Fabric, 4.5-Feet X 300-Feet

The insulation support wire is a versatile product designed to hold blown insulation securely in walls and ceilings. It is compatible with both cellulose and fiberglass insulation, making it a go-to choice for professionals and DIY enthusiasts alike.

Crafted from lightweight and tear-resistant materials, the wire is easy to work with and can be cut to any length required. Its flexibility allows it to be used to tidy up sagging bats in crawl spaces, basements, and garages.

In addition to its primary insulation support function, this wire fabric has an additional use as a multi-purpose fabric. It can be used to protect hardwood floors, countertops, cabinets, and furniture in construction and renovation areas.

The insulation support wire is a must-have for anyone looking for a reliable and versatile product to hold insulation in place. Its high-quality design ensures that it will last for years to come, providing peace of mind and saving time and effort in the long run.

2. Pureshield 5mm Radiant Barrier Insulation Roll

This radiant barrier is an extremely effective solution for reducing heat transfer by reflecting up to 97% of radiant energy. With an impressive R-value of up to 15.67 with one layer and up to 21.10 with two layers, this product is perfect for insulating attics, crawl spaces, walls, and more.

In addition to its excellent thermal insulation properties, this product also serves as a vapor barrier, preventing condensation and remaining unaffected by humidity and moisture. Its 5 mm closed-cell polyethylene foam core, sandwiched between pure aluminum on both sides, also makes it an excellent sound-deadening material.

This radiant barrier is made of supreme quality materials that are strong yet lightweight, with easy installation and cutting. The 5 mm closed-cell polyethylene foam core provides excellent insulation and durability, while the pure aluminum on both sides ensures maximum heat reflection.

Furthermore, this product has a fire rate of Class 1/Class A, ensuring its safety in any situation. It is also non-toxic and will not irritate skin, eyes, or throat, making it safe for anyone to handle.

3. Green Energy Radiant Barrier Attic Insulation

Looking for a reliable and effective radiant barrier for your commercial or industrial space? Look no further than this Perforated No Tear Commercial/Industrial Grade Radiant Barrier. With 500 square feet of double-sided, tear-resistant foil, this barrier is highly reflective, designed to reflect radiant heat instead of absorbing it. Plus, it's remarkably thin to the touch, making it easy to handle without tearing or puncturing.

This radiant barrier is ASTM compliant, meeting the American Society for Testing and Materials' fire and smoke safety requirements for most state and local building codes. It also meets breathability standards for building materials, making it a versatile option for a range of spaces. Whether you need to insulate your attic rafters and floors, garage, workshop, storage unit, barn, warehouse, or older multi-storied home, this radiant foil is up to the task.

What's more, this Perforated No Tear Commercial/Industrial Grade Radiant Barrier comes with a 90-day 100% money-back guarantee. If you're not completely satisfied with your purchase for any reason within the first four months, simply let the seller know, and they'll refund all your money with no hassle.

Installation is a breeze, too – just cut the foil to the desired size with utility scissors, and you're ready to go. There's no need for any special tools or protective equipment, making this barrier an easy and convenient solution for your insulation needs.

In short, if you're looking for a durable, effective, and versatile radiant barrier for your commercial or industrial space, this Perforated No Tear Commercial/Industrial Grade Radiant Barrier is an excellent choice. With its reflective, tear-resistant foil and ASTM compliance, it's sure to meet your insulation needs – and with the seller's money-back guarantee, you can purchase with confidence.

4. Green Energy Foil Wrap For Attic Insulation

Looking for the strongest and most reliable radiant barrier on the market? Look no further than this Heavy Duty Commercial Industrial Grade perforated breathable radiant barrier, which offers an impressive 1,000 square feet per roll. Measuring 4ft wide by 250 feet in length, this barrier is double-sided (5ply) and tear-proof, making it ideal for use in a range of settings.

One of the standout features of this radiant barrier is its exceptional reflectivity. With a 99.97% Reflective E Value, it is highly reflective and designed to reflect radiant heat rather than absorb it. This makes it an excellent choice for use in hot climates where keeping indoor spaces cool is a top priority.

In addition to its impressive performance, this radiant barrier is also fully ASTM compliant. It meets the American Society for Testing and Materials (ASTM) Class 1 Class A fire and smoke safety requirements of most state and local building codes, as well as the breathability standards for building materials. This means that it is a safe and reliable choice for use in a range of settings, including attics, garages, workshops, storage units, barns, warehouses, and older multi-storied homes that lack sufficient insulation.

Thanks to its heavy-duty construction, this radiant barrier is designed to withstand heavy handling and traffic without tearing, puncturing, or overly wrinkling. It can be easily cut with a utility knife or scissors, making installation a breeze. So if you're looking for a top-quality radiant barrier that delivers superior performance and reliability, this Heavy Duty Commercial Industrial Grade barrier is an excellent choice.

5. Reflectix Bp24010 Series Foil Insulation, 24 In. X 10 Ft

This product is designed to prevent or eliminate condensation in various settings, making it an excellent solution for those dealing with moisture-related issues. It is both nontoxic and free of carcinogenic materials, making it safe for use in a variety of environments.

Unlike other products that may require protective clothing, goggles, or a respirator, this product is easy and safe to use. It does not pose any safety risks to the user, allowing for peace of mind during application.

With this product, you can expect a highly effective solution for condensation-related issues without the need for any additional safety gear. Its safety and ease of use make it a top choice for both professionals and those looking for a simple DIY solution.

6. Radiant Barrier Foil Insulation For Commercial Buildings.

This commercial grade product is a highly durable and reliable option for a variety of applications. Its non-perforated design ensures that it will not tear, even under heavy use, making it ideal for use in demanding environments. The heavy-duty 8 mil thickness provides added strength, while the white/foil finish adds a sleek and professional look.

One of the key features of this product is its waterproof design, which makes it perfect for use in areas where moisture is a concern. It is also resistant to oxidation, ensuring that it will maintain its integrity over time. This product is made in the USA and ships from within the country, ensuring that customers receive their order quickly and efficiently.

In addition to its impressive durability and functionality, this product meets all US fire codes and is classified as Class 1 Class A Fire Rated. This makes it a safe and reliable option for use in commercial and industrial settings, as well as in homes and other residential spaces.

7. Frost King Foil Backed Fiberglass Pipe Wrap, 3"x1"x25'

This Fiberglass Pipe Wrap is a highly durable and easy-to-use product that is perfect for those looking to improve their home's energy efficiency. Measuring 1 inch by 3 inches and 25 feet long, this pipe wrap is manufactured in China to the highest quality standards.

The wrap comes with a vapor barrier that is 1 inch thick and foil-backed insulation which helps to cut wasteful heat loss on hot water pipes. This not only helps to lower your energy bills but also reduces your carbon footprint.

In addition to keeping hot water pipes insulated, this pipe wrap also helps to keep cold water pipes from sweating which can lead to water damage and mold growth. The simple one-step installation process makes it easy to handle and install.

8. Johns Manville Intl 90003720 Series R19 23" X39' Kraft Roll

The JOHNS MANVILLE INTL product is a high-quality item that is made in the United States. With an item weight of 20.8 lb, it is sturdy and reliable. The product dimensions are 26.0"L x 19.0"W x 23.5"H, making it the perfect size for a variety of uses.

This product is made by JOHNS MANVILLE INTL, a trusted brand in the industry. They are known for their commitment to quality and craftsmanship, ensuring that every product they make is up to their high standards. With this product, you can be sure that you are getting a reliable and durable item that will last for years to come.

The item weight of 20.8 lb makes this product sturdy and reliable, perfect for a variety of uses. It is not too heavy to move around, but heavy enough to stay in place when needed. The product dimensions of 26.0"L x 19.0"W x 23.5"H make it the perfect size for a variety of uses, from storage to organization and more.

9. Radiantguard Xtreme Heavy Duty Attic Foil Insulation

The commercial grade highly reflective radiant barrier attic foil is a must-have for homeowners who want to lower their utility bills and maintain a consistent temperature throughout the year. This product is designed to BLOCK 95% of radiant heat gain and loss, making it an effective barrier against the elements.

Installation is easy and can be done by anyone with a staple gun. Simply staple the foil to the underside of the attic roof rafters and don't forget to install it on all vertical exterior walls in the attic to ensure complete coverage between the indoor attic area and outdoors. The industrialized strength perforated radiant barrier attic insulation is tear and puncture proof, and the entire roll cuts easily with utility scissors or a hack saw.

Unlike spray foams and reflective radiant barrier paints, this product is non-toxic, non-carcinogenic, fiber-free and maintenance-free. It does not require any special clothing or breathing masks to install, making it a safe and hassle-free option for homeowners.

This product also boasts a Class A / Class 1 (ASTM E-84) highest achievable safety fire rating. This means that it meets fire and smoke requirements for most local, state, and federal building codes, adding an extra layer of safety and protection to your home.

Investing in this highly reflective radiant barrier attic foil is a smart choice for any homeowner looking to save money on their utility bills while maintaining a comfortable indoor temperature. Its durability, ease of installation, and safety features make it a top choice for anyone in need of an effective and reliable insulation solution.

10. Owens Corning R-19 Faced Fiberglass Roll 23" Wide

Introducing the Individual Faced Roll – a premium fiberglass insulation product that guarantees excellent thermal and acoustical control in any space. This roll boasts a generous size of 23 inches wide, 39.2 feet long, and 6.25 inches deep, making it ideal for use in 2×6 walls, floors, crawlspaces, and attics.

One of the key advantages of this fiberglass insulation is its superior dust control capabilities. Compared to other similar products in the market, the EcoTouch PINK Fiberglass insulation produces less dust, ensuring a cleaner and safer installation process. Moreover, it has excellent stiffness and recovery characteristics, ensuring that it stays in place and maintains its insulating properties over time.

Thanks to its compression packaging from Owens Corning, this roll is easy to handle and install on the job site. It saves time and effort, allowing you to complete your project with ease and efficiency.

The Individual Faced Roll is certified by GREENGUARD GOLD, ensuring that it meets strict standards for indoor air quality and environmental responsibility. It is also validated to be Formaldehyde-free, making it a safe and healthy choice for your home or building.

Best Insulation For Mobile Home Walls FAQs

Are there any downsides to using fiberglass insulation in mobile home walls?

Fiberglass insulation is a popular choice for mobile home walls due to its affordability, ease of installation, and energy efficiency. However, there are some downsides to using fiberglass insulation in mobile home walls.

Firstly, fiberglass insulation is not fire-resistant and can melt or burn when exposed to high temperatures. This can lead to rapid spread of fire in case of a fire breakout. Secondly, fiberglass insulation can be a health hazard if not properly installed or handled with care. The small fibers can irritate the skin, eyes, and lungs causing respiratory problems.

Thirdly, fiberglass insulation is prone to moisture retention, which can lead to mold and mildew growth. This can cause damage to the walls and pose a serious health risk to the occupants. Lastly, fiberglass insulation may not be suitable for extreme climates, such as very hot or very cold temperatures, as it may not provide adequate insulation.

It is important to consider these factors before choosing fiberglass insulation for mobile home walls and to consult with a professional to ensure proper installation and handling.

Can I install insulation in my mobile home walls myself, or do I need a professional?

Installing insulation in mobile home walls is a task that can be done by homeowners themselves. However, before starting the project, it is important to gather all the necessary tools and materials and to research the process thoroughly. This includes understanding the different types of insulation available and the R-value required for your specific home.

It is also important to note that some mobile homes may have unique construction methods that could make insulation installation more challenging. For example, some mobile homes have wall cavities that are not standard sizes, which could require custom-cut insulation.

If you are confident in your ability to complete the project and have the necessary tools and materials, then you can install insulation in your mobile home walls yourself. However, if you are uncertain or feel uncomfortable with the process, it is advisable to seek the help of a professional. A professional can ensure that the insulation is installed correctly, and can also provide advice on the best insulation materials for your home.

Can I use recycled insulation materials in my mobile home walls?

Yes, you can use recycled insulation materials in your mobile home walls. In fact, using recycled insulation materials is a great way to reduce your environmental impact and save money on energy costs.

There are several types of recycled insulation materials available, including recycled denim, recycled newspaper, and recycled plastic. Each type has its own unique benefits and drawbacks, so it's important to choose the right one for your specific needs.

Recycled insulation materials can help keep your mobile home cool in the summer and warm in the winter, which can reduce your reliance on heating and cooling systems. They can also help reduce noise pollution and improve indoor air quality, which is especially important if you or someone in your family has allergies or respiratory issues.

When choosing recycled insulation materials, make sure to check the R-value, which measures the material's ability to resist heat flow. The higher the R-value, the more effective the insulation will be at keeping your home comfortable.

Overall, using recycled insulation materials in your mobile home walls is a great choice for both your wallet and the environment.

How can I ensure proper insulation installation in my mobile home walls?

Proper insulation installation is crucial to ensure that your mobile home walls provide adequate thermal protection. Here are some steps to ensure proper insulation installation:

1. Choose the right type of insulation material. The most common insulation materials used in mobile homes are fiberglass, foam, and cellulose. Each has its own advantages and disadvantages, so choose the one that best suits your needs and budget.

2. Ensure that the insulation material is of the right thickness. The recommended thickness for insulation in mobile home walls is usually 2-3 inches.

3. Check for gaps, holes, or other openings in the wall cavity. These can allow air to leak in or out, reducing the effectiveness of the insulation. Seal any openings with caulking or foam sealant before installing the insulation.

4. Install the insulation properly. Follow the manufacturer's instructions carefully to ensure that the insulation is installed correctly. This may involve cutting the insulation to size, stapling or taping it in place, or using a blowing machine to fill the wall cavity.

5. Consider hiring a professional. If you're not confident in your ability to install insulation properly, consider hiring a professional to do the job for you. A professional insulation installer can ensure that the insulation is installed correctly and provide you with peace of mind.

By following these steps, you can ensure that your mobile home walls are properly insulated, which can help to lower your energy bills and increase your comfort.

How does the insulation R-value affect the energy efficiency of my mobile home?

The insulation R-value plays a crucial role in determining the energy efficiency of your mobile home. R-value refers to the capacity of insulation to resist heat flow. The higher the R-value, the better the insulation's performance, as it will keep your home cooler in the summer and warmer in the winter. In mobile homes, insulation is particularly important as they tend to lose heat faster than traditional homes. Therefore, it is recommended to have an R-value of at least R-30 in the attic and R-11 in the walls of your mobile home. Good insulation will help reduce the use of heating and cooling systems, which means lower energy bills and a more comfortable home. Additionally, higher insulation R-values can increase the resale value of your mobile home. In conclusion, a higher insulation R-value translates to higher energy efficiency in your mobile home, which means cost savings and increased comfort.

How long does insulation for mobile home walls typically last before needing replacement?

The lifespan of insulation for mobile home walls can vary depending on factors such as the type of insulation used, the climate in which the home is located, and the level of maintenance performed. Generally, if the insulation is well-maintained and not damaged, it can last for several decades. However, if there is water damage, pest infestations, or other issues, the insulation may need to be replaced sooner. It's important to regularly inspect the insulation in your mobile home and address any problems promptly to ensure it lasts as long as possible. If you're unsure about the condition of your insulation, it's a good idea to consult with a professional contractor who can assess your mobile home and recommend any necessary repairs or replacements.

How much insulation is needed for mobile home walls?

The amount of insulation needed for mobile home walls can vary depending on several factors, such as the climate zone, the type of heating and cooling system, and the age and condition of the mobile home.

As a general rule of thumb, mobile homes built before 1976 typically have little to no insulation in their walls, while newer mobile homes may have some insulation installed during manufacturing. However, the amount of insulation in these homes may not be sufficient for optimal energy efficiency.

To determine how much insulation is needed for mobile home walls, it is recommended to consult with a professional insulation contractor or energy auditor. They can assess the current insulation levels and recommend the appropriate amount of insulation based on the specific needs of the home.

In general, adding insulation to mobile home walls can help reduce energy costs and improve comfort levels inside the home. The recommended R-value (a measure of insulation's ability to resist heat flow) for mobile home walls typically ranges from R-11 to R-21, depending on the geographic location and climate zone.

What are the benefits of using spray foam insulation in mobile home walls?

Spray foam insulation is a popular choice for mobile home owners due to its numerous benefits. The first benefit is that it provides an airtight seal that prevents air infiltration, which is a common problem in mobile homes. This helps to keep the interior temperature consistent, which can lead to significant energy savings. Additionally, spray foam insulation is more efficient than traditional insulation, providing a higher R-value per inch of thickness. This means that you can achieve the same level of insulation with less material, which can save you money on installation costs.

Another benefit of spray foam insulation is that it can help to reduce noise transmission. This is particularly important in mobile homes, as they tend to have thinner walls than traditional homes. The foam can act as a sound barrier, reducing the amount of noise that enters the home. Additionally, spray foam insulation is resistant to moisture and mold, which can be a problem in mobile homes that are located in humid areas.

Overall, spray foam insulation is a great option for mobile home owners who want to improve the energy efficiency and comfort of their home. It provides a range of benefits that can help to reduce energy costs, improve indoor air quality, and increase the overall value of the home.

What is the cost difference between different types of insulation for mobile home walls?

The cost of insulation for mobile home walls can vary depending on the type of insulation you choose. There are several types of insulation available for mobile homes, including fiberglass, spray foam, and rigid foam insulation.

Fiberglass insulation is the most common type of insulation used in mobile homes and is generally the most affordable option. The cost of fiberglass insulation for mobile home walls can range from $0.30 to $0.60 per square foot.

Spray foam insulation is a more expensive option but provides better insulation and energy efficiency. The cost of spray foam insulation for mobile home walls can range from $1.00 to $2.00 per square foot.

Rigid foam insulation is another option for mobile home walls and provides excellent insulation and moisture resistance. The cost of rigid foam insulation for mobile home walls can range from $0.75 to $1.50 per square foot.

It is important to consider the long-term benefits of insulation when making a decision on which type to choose. While spray foam and rigid foam insulation may be more expensive up front, they can provide significant energy savings and potentially pay for themselves over time.

What type of insulation is best for mobile home walls?

The type of insulation that is best for mobile home walls depends on various factors such as climate, budget, and personal preferences. However, one of the most commonly used insulation materials for mobile home walls is fiberglass insulation. This type of insulation is affordable, easy to install, and effective in reducing heat loss or gain. Another popular option is spray foam insulation, which provides a higher R-value than fiberglass and can also help to seal air leaks. However, spray foam insulation is more expensive and requires professional installation. Other types of insulation that can be used for mobile home walls include cellulose insulation, foam board insulation, and reflective insulation. It is important to consult with a professional to determine the best type of insulation for your specific mobile home and needs.